Medium temperature: —29—425 ° C

Operation method: manual

Medium: water, steam, oil, etc.

Caliber: DN40-300mm

Pressure: 1.6-4.0mpa

Body material: ASTM A216 WCB, LCB, WC6, WC9, CF8, CF8M

Connection method: flange

| DIN F5 Non-rising Stem Gate Valve Material of main parts | ||||

| Part Name | material | |||

| Body / bonnet | ASTM A216 WCB、LCB | Alloy steel, stainless steel | ||

| gate | ASTM A216 WCB、LCB | Alloy steel, stainless steel | ||

| Valve stem | ASTM A182 F6a、F304、F316 | |||

| Stem nut | Ductile iron | |||

Application: Cut off or connect the pipeline medium on the roads under various working conditions such as petroleum, chemical, pharmaceutical, chemical fertilizer, electric power.

| DIN F5 Non-rising Stem Gate Valve Performance specifications | |||||||

| Model | Nominal Pressure (mpa) | Test Pressure(mpa) | Proper Temperature | Applicable Medium | |||

| Strength | Seal | ||||||

| DIN F5 Non-rising Stem Gate Valve-16 | 1.6 | 2.40 | 1.76 | —29—425℃ | Water, steam, oil, etc. | ||

| DIN F5 Non-rising Stem Gate Valve-25 | 2.5 | 3.75 | 2.75 | ||||

| DIN F5 Non-rising Stem Gate Valve-40 | 4.0 | 6.00 | 4.40 | ||||

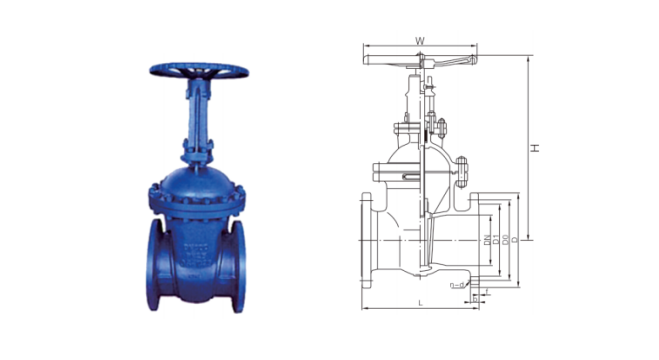

| DIN F5 Non-rising Stem Gate Valve Dimensions and connection dimensions | |||||||

| Model | Nominal Diameter (mm) | size(mm) | |||||

| L | D | D0 | D1 | g-f | n-φd | ||

| 16 | 40 | 240 | 150 | 110 | 88 | 18-3 | 4*φ18 |

| 50 | 250 | 165 | 125 | 102 | 18-3 | 4*φ18 | |

| 65 | 270 | 185 | 145 | 122 | 18-3 | 8*φ18 | |

| 80 | 280 | 200 | 160 | 138 | 20-3 | 8*φ18 | |

| 100 | 300 | 220 | 180 | 158 | 20-3 | 8*φ18 | |

| 125 | 325 | 250 | 210 | 188 | 22-3 | 8*φ18 | |

| 150 | 350 | 285 | 240 | 212 | 22-3 | 8*φ22 | |

| 200 | 400 | 340 | 295 | 268 | 24-3 | 12*φ22 | |

| 250 | 450 | 405 | 355 | 320 | 26-3 | 12*φ26 | |

| 300 | 500 | 460 | 410 | 378 | 28-4 | 12*φ26 | |

| 25 | 40 | 240 | 150 | 110 | 88 | 20-3 | 4*φ18 |

| 50 | 250 | 165 | 125 | 102 | 20-3 | 4*φ18 | |

| 65 | 270 | 185 | 145 | 122 | 22-3 | 8*φ18 | |

| 80 | 280 | 200 | 160 | 138 | 24-3 | 8*φ18 | |

| 100 | 300 | 235 | 190 | 162 | 24-3 | 8*φ22 | |

| 125 | 325 | 270 | 220 | 188 | 26-3 | 8*φ26 | |

| 150 | 350 | 300 | 250 | 218 | 28-3 | 8*φ26 | |

| 200 | 400 | 360 | 310 | 278 | 34-3 | 12*φ26 | |

| 250 | 450 | 425 | 370 | 335 | 36-3 | 12*φ30 | |

| 300 | 500 | 485 | 430 | 395 | 40-4 | 16*φ30 | |

| 40 | 40 | 240 | 150 | 110 | 88 | 20-3 | 4*φ18 |

| 50 | 250 | 165 | 125 | 102 | 20-3 | 4*φ18 | |

| 65 | 270 | 185 | 145 | 122 | 22-3 | 8*φ18 | |

| 80 | 280 | 200 | 160 | 138 | 24-3 | 8*φ18 | |

| 100 | 300 | 235 | 190 | 162 | 24-3 | 8*φ22 | |

| 125 | 325 | 270 | 220 | 188 | 26-3 | 8*φ26 | |

| 150 | 350 | 300 | 250 | 218 | 28-3 | 8*φ26 | |

| 200 | 400 | 375 | 320 | 285 | 34-3 | 12*φ30 | |

| 250 | 450 | 450 | 385 | 345 | 38-3 | 12*φ33 | |

| 300 | 500 | 515 | 450 | 410 | 42-4 | 16*φ33 | |

Tips:

1.Compact structure, reasonable design, good valve rigidity, smooth passage.

2.The use of flexible graphite packing, reliable sealing, light and flexible operation

Applications:

Industrial applications: Petroleum, Chemical, Paper Making, Fertilizer, Coal Mining,water treatment and etc.

Product Advantages:

1.We have Sand or Precision casting technology,So we can as your drawing design and production.

2.Customers' logos are available cast on the valve body.

3. All our casting with tempering procedure before Processing.

4. Use the CNC lathe during whole process.

5. The disc sealing surface use plasma welding machine welding.

6. Every valve must be tested before delivery from the factory, only qualified ones can be shipped.

7.The kind valve we usually use Bags to package, We also can according to specific customer's requests.

8. Production Obviously advantages:

- No groove design at the bottom of the valve prevents the leakage or damage caused by the accumulation of the valve, this design also has small resistance to the fluid.

- Small torque when it is open and close.

- No restriction torwards the fluid's direction and no turbulence to the flow, it will also not reduce the pressure.

- Simpler structure, better workmanship and shorter face to face dimension.

- High-quality rubber covered on the surface can increase its flexibility and prolong its service life.

- Epoxy painted inside is anti-corrosion as well as avoiding the seconday pollution to the fluid.

Company Advantages:

1.We are manufacturer Since 1992.

2.CE,API,ISO approved.

3.Fast delivery.

4.Low price with high quality.

5.Professional work Team!

Copyright © Hebei Yaosheng IM & EX Trading Co.,Ltd. All Rights Reserved |Sitemap | Technical Support: